Views: 0 Author: Site Editor Publish Time: 2025-07-17 Origin: Site

When you need precise, controlled dispensing results, selecting the right plastic cartridge nozzle matters more than you think. The right nozzle helps you control every drop of material, whether you work on large construction projects or detailed industrial applications. New Chang-An Plastic Enterprise Co., Ltd. offers professional PE plastic nozzles that meet diverse dispensing needs for adhesives, sealants, and coatings. Quality nozzles make your work more efficient and deliver superior results every time.

Choose nozzles with appropriate tip configurations for optimal flow control. This ensures neat and precise application for your specific requirements. Select nozzles manufactured from durable PE plastic materials that resist chemical degradation and maintain compatibility with your adhesive or sealant formulations. Consider ergonomic designs that provide comfortable handling during extended use while reducing operator fatigue. Utilize nozzles that offer precise dispensing control for various materials and viscosities.

PE plastic nozzles from New Chang-An are manufactured using high-quality polyethylene materials. This construction provides excellent chemical resistance against most adhesives, sealants, and coatings. PE material maintains dimensional stability under normal operating conditions while offering cost-effective performance. The material resists degradation from common construction chemicals and industrial adhesives.

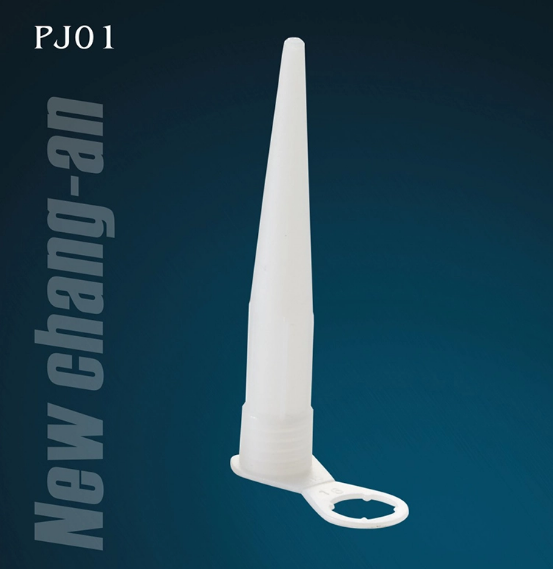

Professional plastic cartridge nozzles are available in multiple configurations to accommodate various dispensing requirements. Different tip geometries provide options for fine pinpoint streams or wider application patterns. The versatile design ensures compatibility with standard cartridge systems used in construction, automotive, and industrial applications.

Quality PE plastic nozzles deliver consistent flow characteristics essential for professional applications. The engineered tip design provides controlled material flow while minimizing waste and ensuring accurate placement. This precision is critical for sealant applications in construction and automotive repair where accuracy affects performance.

PE plastic construction offers excellent durability for repeated use in demanding environments. The material resists cracking and maintains structural integrity under normal operating pressures. This reliability ensures consistent performance throughout the product lifecycle, reducing replacement frequency and operational costs.

Construction professionals rely on PE plastic nozzles for sealant and adhesive dispensing in various building applications. These nozzles provide precise control for joint sealing, weatherproofing, and structural bonding. The chemical resistance of PE material ensures compatibility with construction-grade sealants and adhesives commonly used in building projects.

Automotive applications require precise dispensing of sealants and adhesives for vehicle assembly and repair. PE plastic nozzles offer the accuracy needed for windshield installation, body panel bonding, and seam sealing. The material compatibility ensures reliable performance with automotive-grade adhesives and sealants.

Manufacturing facilities use PE plastic nozzles for various adhesive and coating applications. The consistent flow characteristics help maintain quality standards in production environments. Chemical resistance properties make these nozzles suitable for industrial adhesives and specialty coatings.

PE plastic nozzles serve general-purpose applications where cost-effective, reliable dispensing is required. The versatile design accommodates various materials while providing consistent performance across different applications.

PE plastic nozzles offer specific material properties essential for dispensing applications:

Chemical Resistance: Compatible with most adhesives, sealants, and coatings

Temperature Range: Suitable for standard operating temperatures

Pressure Rating: Designed for typical cartridge system pressures

Durability: Resistant to cracking and dimensional changes

Professional PE plastic nozzles are designed for compatibility with standard cartridge systems. The connection interface matches industry-standard cartridge threading, ensuring easy installation and secure attachment. This compatibility allows for use with various cartridge sizes and configurations.

Engineered tip design provides controlled flow characteristics suitable for various material viscosities. The orifice configuration minimizes turbulence while maintaining consistent flow rates. This design helps achieve uniform application patterns and reduces material waste.

Consider your specific dispensing requirements when selecting PE plastic nozzles:

Material Type: Ensure compatibility with your adhesive or sealant

Viscosity: Match nozzle design to material flow characteristics

Application Pattern: Select appropriate tip configuration

Precision Needs: Choose based on accuracy requirements

Volume Requirements: Consider flow rate needs

Evaluate operating conditions that may affect nozzle performance:

Temperature Range: Verify compatibility with operating temperatures

Chemical Exposure: Confirm resistance to environmental chemicals

Pressure Requirements: Ensure adequate pressure rating

Durability Needs: Consider replacement frequency requirements

PE plastic nozzles offer excellent value for most dispensing applications. The combination of performance, durability, and cost makes them ideal for high-volume operations. Consider total cost of ownership including initial price, replacement frequency, and performance benefits.

New Chang-An Plastic Enterprise Co., Ltd. maintains stringent quality control throughout the manufacturing process. Established in 1987, the company brings decades of experience to plastic component manufacturing. Advanced production techniques ensure consistent quality and dimensional accuracy.

PE plastic materials meet industry standards for chemical resistance and dimensional stability. Quality control testing verifies material properties and performance characteristics. Batch testing ensures consistency across production runs.

Each nozzle design undergoes performance testing to verify flow characteristics and dimensional accuracy. Quality assurance protocols ensure products meet specified performance criteria before shipment.

New Chang-An's technical team provides application engineering support to help select optimal nozzle configurations. Expert guidance ensures proper nozzle selection for specific dispensing requirements. Technical consultation helps optimize dispensing performance and reduce operational issues.

Custom nozzle configurations are available for specialized applications. Engineering support helps develop custom solutions for unique dispensing requirements. Prototype development services enable testing before full production implementation.

Comprehensive technical documentation supports proper nozzle selection and application. Specification sheets provide detailed performance data and compatibility information. Installation and usage guidelines ensure optimal performance.

PE plastic nozzles for cartridge dispensing provide reliable, cost-effective solutions for professional applications. The combination of chemical resistance, durability, and precise flow control makes them ideal for construction, automotive, and industrial use. New Chang-An Plastic Enterprise Co., Ltd. offers quality PE plastic nozzles backed by decades of manufacturing experience and technical expertise.

For optimal dispensing performance, select nozzles that match your specific application requirements. Consider material compatibility, flow characteristics, and environmental conditions when making your selection. Professional consultation ensures you choose the right nozzle configuration for your dispensing needs.

PE plastic nozzles are compatible with most adhesives, sealants, and coatings used in construction and industrial applications. The chemical resistance properties of PE material ensure reliable performance with standard formulations. Always verify compatibility with specific material formulations before use.

Consider your dispensing requirements including material viscosity, application pattern, and precision needs. New Chang-An's technical team can provide guidance on optimal nozzle selection based on your specific application requirements. Technical consultation ensures proper nozzle configuration selection.

New Chang-An PE plastic nozzles are manufactured to meet industry quality standards for dispensing applications. Quality control processes ensure consistent performance and dimensional accuracy. Material properties are verified through testing to ensure reliability.

Yes, PE plastic nozzles are designed to provide precise dispensing control suitable for professional applications. The engineered tip design ensures controlled flow characteristics and accurate material placement. Precision capabilities meet requirements for construction and industrial applications.

New Chang-An Plastic Enterprise Co., Ltd. provides comprehensive technical support for nozzle selection and application guidance. Contact their technical team for assistance with specific dispensing requirements and product recommendations. Professional consultation ensures optimal nozzle selection for your applications.